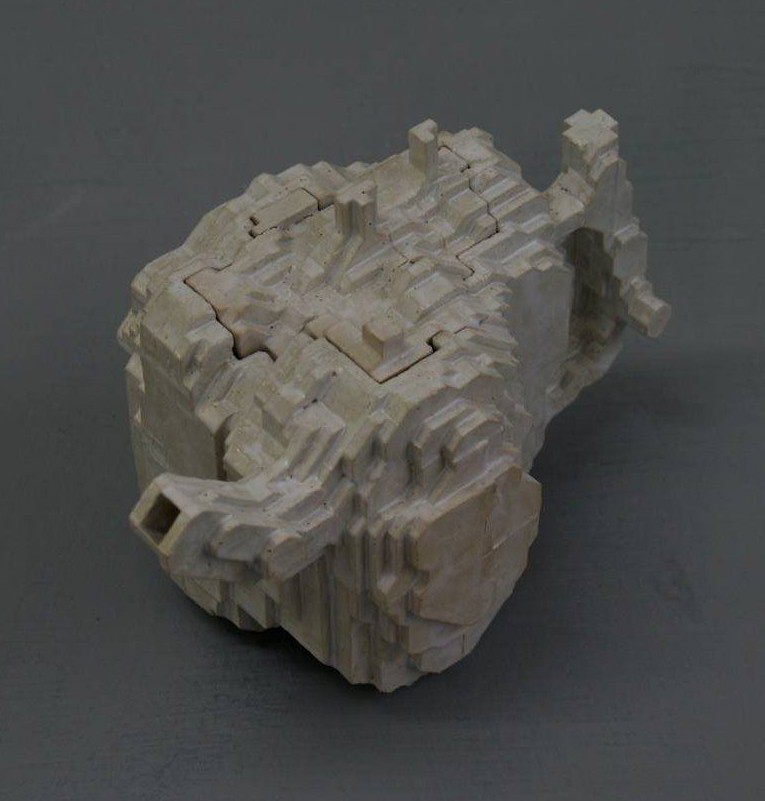

Quantised Tea Set

This work was conceptualised using a top-down approach. The decision was made to build ceramic teapots in the ‘quantised’ style of the Quantum Landscape drawings, and only afterwards, the problem of implementation was addressed.

The implementation turned out to be very challenging and several approaches were tried and rejected until a method was found. The final process is very laborious but quite effective. Unfortunately, no photographic record of the building process exists.

(See text below for more information).

Teapot

Stoneware

180 x 120 x 105mm

2007

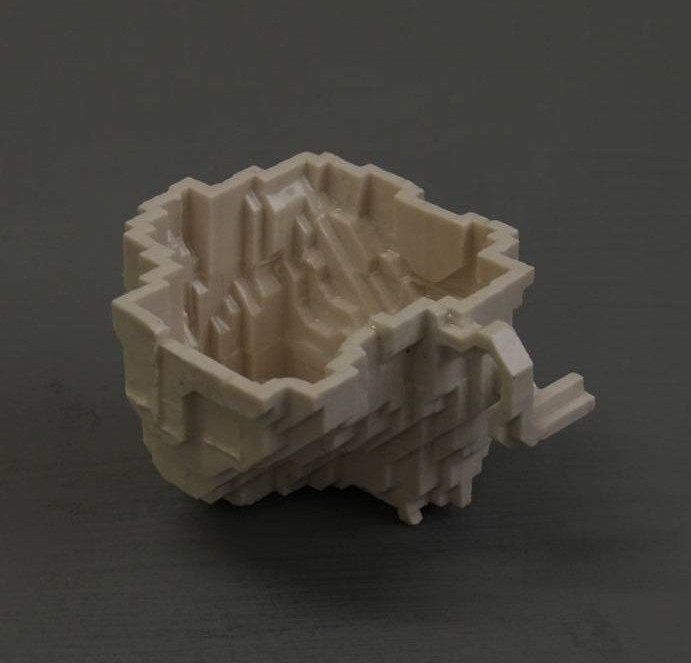

Cup

Porcelain

97 x 85 x 67mm

2007

Cup

Porcelain

105 x 82 x 63mm

2007

The major difficulty of making these forms out of clay is the requirement of modelling both the inside and outside surfaces. Traditional methods such as slip moulding cannot be used due to the shrinkage of the clay – the form would become stuck on the mould, and then split as drying and shrinking continued.

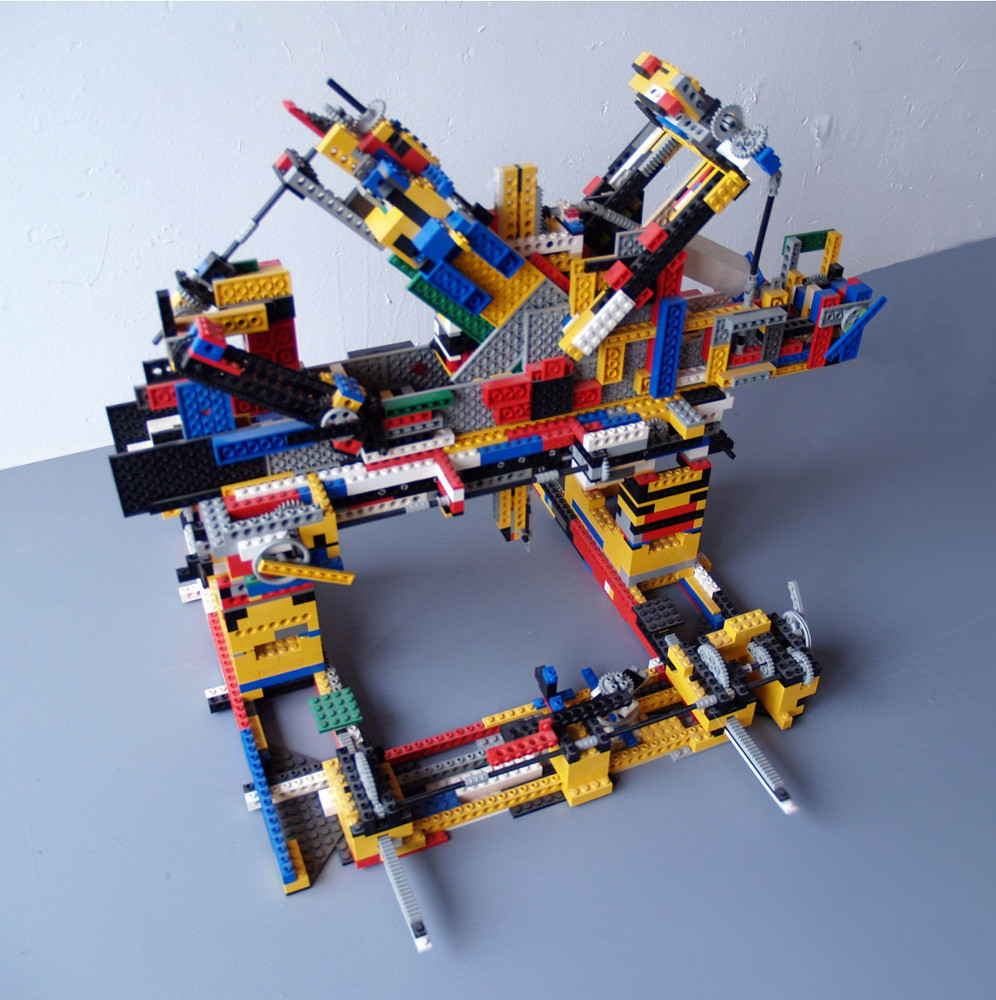

The final production method was a special modular moulding system which I developed made from modified Lego bricks. The making process was extremely time-consuming. About six weeks for the teapot featured above – I kept a detailed work diary during this period, and this includes time taken to make the design at the start, assemble the moulds for each part, mould each part, extract each part at the semi-dry stage and join the parts, and the time to disassemble the moulds and clean each part. The parts of the moulds were stuck together with non-waterproof glue and each surface had to be cleaned and scraped thoroughly ready for the next use. I manufactured a large number of these small mould parts, but still, for a teapot-sized piece I might have to do two batches, using up all of the parts, to make a first lot of parts, then extracting them, breaking up the moulds and cleaning all the bits to re-use them. I had a part time job at the time but I was spending nearly every other available other hour making these and since I was spending all of my spare time alone I put some thought into how I could carry on doing the work whilst being a bit more sociable. One of the most time consuming jobs was assembling the mould parts, so I developed the backpack as a mobile system, with space to store a few mould parts, so that I could take it to work at other people’s houses.

Quantised Crockery System – Mobile Backpack Mould Building Kit

The mould pieces are made from modified Lego bricks all cut down to fit a grid size of half the width of a standard one unit Lego brick.

I built the backpack with the intention of taking it to work at other people’s houses – I wanted to find a way of continuing work whilst bringing social possibilities in to my the lonely life which I was leading.

Quantised Crockery System – Scraping Machine

This is an earlier experiment aborted at early testing stage due to obvious impracticality.

At this stage, I was attempting to work by the process of gradually scraping material away from a block of wet clay.

The scraping tool is capable of moving in ten different directions: the six cardinal directions, up, down, left, right, back, forward, plus four diagonals, up-left, down-right, up-right, down-left. In order to facilitate this I had to make some quite inventive Lego Technic mechanisms.